In controlled environments such as cleanrooms, the use of appropriate cleanroom wipes is crucial to maintaining cleanliness and preventing contamination. These specialized wipes are designed to remove particles, dust, and other contaminants without leaving lint or residues behind.

cleanroom wipes are lint-free cleaning materials used in sensitive environments like laboratories, pharmaceutical facilities, and electronics manufacturing. These wipes ensure that the air and surfaces remain free from contaminants that could disrupt processes or damage sensitive equipment.

Contamination control is essential in cleanrooms to maintain sterile conditions. Using regular cleaning materials in these environments could lead to particle buildup, which might interfere with research, production processes, and product quality.

Lint-free cleanroom wipes for electronics are essential in environments where static-sensitive components are manufactured or handled. These wipes ensure that no fibers or dust are transferred to the equipment, which could cause performance issues or even equipment failure. These wipes are typically made from materials like polyester or cellulose, which are both highly absorbent and free from any residues.

cleanroom wipes for pharmaceutical applications are specifically designed for use in the pharmaceutical industry where sterility and contamination control are critical. These wipes must meet stringent regulatory standards and are made from high-quality materials to prevent any particles from being transferred to drugs, medical devices, or sterile equipment.

Eco-friendly CLEANROOM WIPES for clean environments are becoming increasingly popular as businesses move toward more sustainable practices. These wipes are made from biodegradable materials that break down quickly, reducing the environmental impact while still offering high performance in contaminant control.

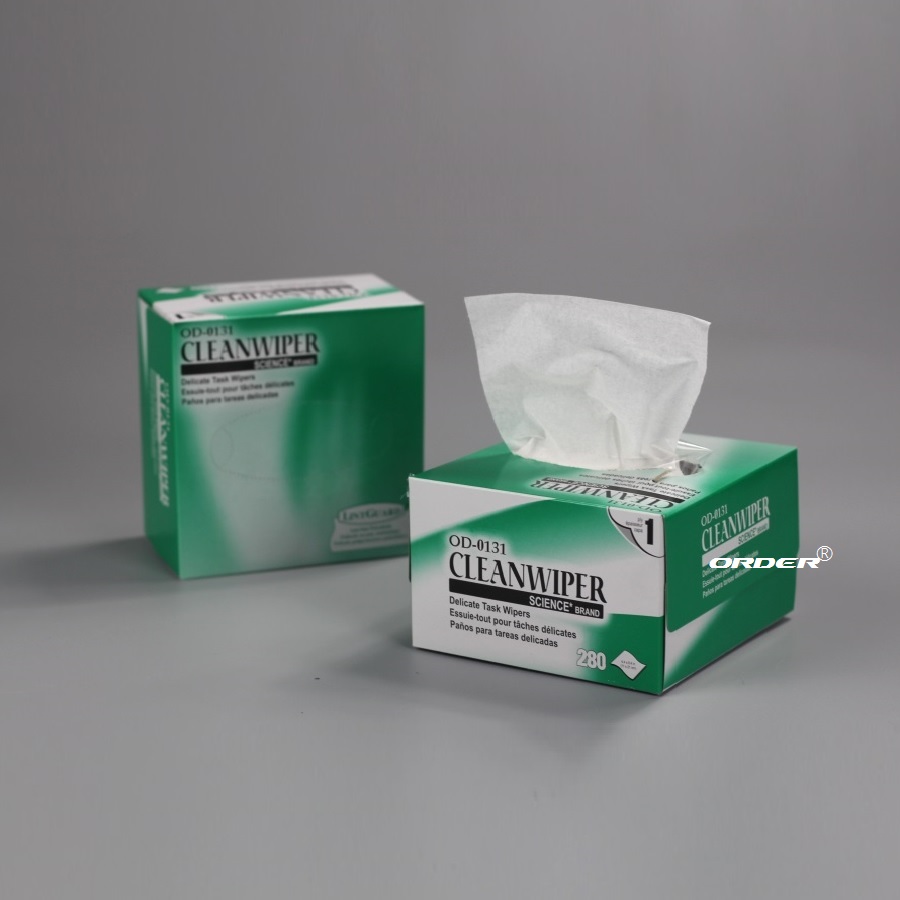

When selecting CLEANROOM WIPES, it's essential to consider their absorbency and durability. High-quality wipes are designed to hold up to multiple uses and clean large surfaces without tearing or leaving residues.

In environments where electronics are handled, CLEANROOM WIPES with ESD (Electrostatic Discharge) protection are crucial. These wipes prevent static electricity buildup, which can damage sensitive components in the manufacturing process.

CLEANROOM WIPES should be compatible with various cleaning solutions. Some wipes are pre-saturated with cleaning agents, while others can be used with solutions chosen based on the needs of the environment. Proper compatibility ensures that the wipes won’t degrade or leave residues when used with specific chemicals.

Choosing the right wipes involves understanding the specific needs of your cleanroom environment, such as the required cleanliness level and the nature of the contaminants being removed.

The most common types of CLEANROOM WIPES are made from materials such as polyester, cellulose, and microfiber. These materials offer different levels of absorbency, durability, and lint-free properties. The choice depends on the specific needs of the cleanroom environment.

The frequency of replacement depends on usage and the level of contamination. For high-traffic or high-contamination areas, wipes may need to be replaced frequently, while in less intensive environments, they may last longer. Always follow manufacturer recommendations and industry guidelines for optimal results.

No, regular wipes should never be used in cleanrooms as they may introduce contaminants like lint, fibers, and chemicals. Specialized CLEANROOM WIPES are designed to maintain the high standards of cleanliness required in these controlled environments.

CLEANROOM WIPES are essential in maintaining a contamination-free environment in industries such as pharmaceuticals, electronics, and food manufacturing. Choosing the right wipes depends on factors like absorbency, ESD protection, and compatibility with cleaning solutions. By selecting high-quality, industry-specific wipes, you can ensure the cleanliness and integrity of your cleanroom operations.